Tip 1: How to make room noise isolation

Tip 1: How to make room noise isolation

In any car there is a huge amountsources of noise of a different nature. In business class cars, noise insulation is given great attention. In cars, which are mainly focused on the middle class, noise protection is not always enough. Noise isolation implies under itself a muffling of transmission and engine noise, as well as a reduction in the vibrations of the metal parts of the car when driving, which is achieved by gluing various materials on the body parts.

Instructions

1

First, make soundproofing doors. To do this, remove the car door trim. It is usually fastened with screws that are in the handle. Unfasten the "bedbugs" and detach the skin, lifting it from the bottom up. Disconnect the wires that fit the power window.

2

Tear off the plastic wrap that wasis attached to the door in the factory. Degrease the surface. Cut and glue the outer part of the door with the soundproofing material (on the inside). Make sure that the material is snug against the surface, otherwise it will not have the proper effect, and when heated, it will fall off altogether.

3

Close the factory mounting holes tocreate a closed volume for better sounding of the speakers. Do the whole procedure with all the doors. If you want, at the same time lay the acoustic wires to install the speakers in the door. Glue with thin strips of the fitting of the skin to the door.

4

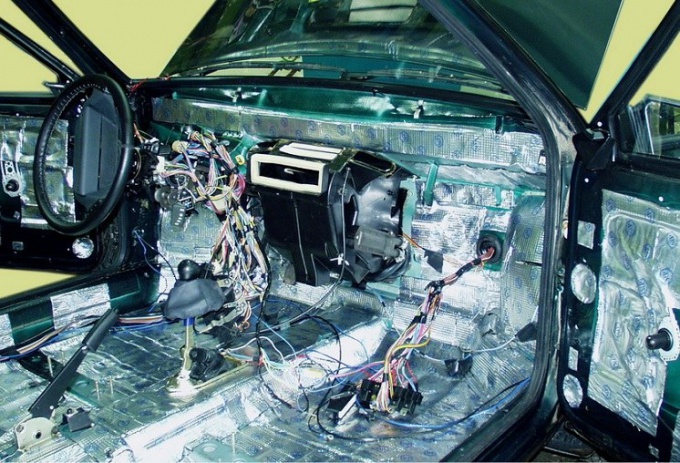

Then run soundproofing Salon. To do this, disassemble it to the ground. Apply a layer of insulation that will absorb vibration to the surface of the body: floor, arches, wings. Then glue it all with a second layer, which serves to absorb the noise. When assembling Salon screw the bolts that secure the paneling into place, to avoid confusion.

Tip 2: How to make noise insulation on Ford Focus

Robust sound insulation of the car -an indispensable condition for a comfortable trip. Especially it is important for long travels along noisy city streets. To make your car more comfortable, just trim his interior with a layer of vibration and soundproof material.

You will need

- vibroplast, noise insulation, knife, screwdriver.

Instructions

1

First, install soundproofing on all doors Ford Focus. To do this, unscrew all fasteners and unfastenso-called "bedbugs" on which the skin is fastened, with a screwdriver. In order not to damage the paint coating, wrap the screwdriver with two layers of electrical tape. Carefully remove the trim by unplugging the handle cable and the wires that lead to the power window. As a rule, polyethylene film is glued to the door from the factory, tear it off. If there is native noise insulation, leave it, and put a new one on top.

2

Degrease the surface with any suitablecompound, and glue the outer wall of the door with the vibration plate, only on the inside. Tightly roll it, otherwise the desired effect will not be achieved, and if the car is left in the sun, it will simply become unstuck. After that, the soundproofing film, cover the technological holes on the doors. You can cut them and glue them separately, making a reserve of 2-3 cm, and you can use one piece, but in this case, the doors will become too heavy. Glue soundproofing all the places of touching the skin to the door, for which slice it with strips 2-3 cm wide.

3

Disassemble the interior completely, removing all the finishingmaterials. When working, be careful not to lose the fixing bolts and "bugs", which will affect later when assembling. Then, on a cleaned and skimmed frame, apply a layer of vibration plate, tightly fitting it to the surface of the body, including the floor, arches and wings. The second layer of glue soundproofing for the body on a sticky basis, and the entire surface as a whole, avoiding gaps as much as possible. Check the integrity of both layers, then proceed to the back installation of the skin, seating it tightly on the soundproofing.

4

Buying a vibration plate for noise insulation Ford Focus, get a consultation from the seller, often this material for doors and body comes with different properties.

Tip 3: How to make a noise insulation on the WHA

As most people should knowdomestic motorists, cars, descended from the factory conveyors of VAZ, require a number of significant improvements. In particular, it concerns the noise isolation of the car interior.

Material and tools

Before you start to bring to mind the car showroom,it is necessary to have at your disposal the following: - Insulation material ("Vibroplast" can be used), approximately 14 sheets 0,6х0,9 meters, - Solvent - 1 liter, - Sharp knife, preferably shoe, - Spatula - Construction hair dryer - Screwdriver.The process itself

The work begins with the removal of the plating in the cabincar. The roof, doors, and also the lining present on the side surfaces of the rear seats and the arches of the rear wheels are freed from the shell. When removing the cladding, care should be taken not to damage the fasteners-pistons. After removal of the cladding, it is necessary to remove all factory vibroinsulation, which according to the concept of the designers of the car should at least somehow protect the interior of the cabin from external noise. Since there is practically no benefit from such protection, it should be removed without a trace. In places where the vibration isolation is especially carefully glued, it should be scraped off using a spatula or heated adhesive using a construction hair dryer. After the vibration isolation has been removed, it is necessary to thoroughly degrease the surfaces to which the soundproofing material will adhere. For this procedure, you should use a solvent. When the preparatory work is finished, you can proceed, in fact, to gluing the noise insulation. You need to start from the door, while "Vibroplatform" does not need to be saved, but on the contrary, it is necessary to glue the entire surface, as carefully as possible. For gluing the front surfaces of doors, it is advisable to use solid sheets of material, for work with hard-to-reach places, "Vibroplast" should be cut into small pieces. The noise insulation of the roof of the car, as well as the surfaces of the trunk, rear seats and arches of the rear wheels, is done on the same principle. The only difference is that for smooth and dense gluing of the material on the round surface of the arches of the wheels, it is necessary to make cuts on its surface diagonally. After the noise insulation material is glued, it is necessary to smooth it, pre-warmed up with a hair dryer.Tip 4: How to make noise insulation doors to the WHA

Sound insulation of VAZ cars wasalways in demand - cars produced in Togliatti do not have good sound-absorbing upholstery. And if earlier the choice of materials for such purposes was small, today manufacturers offer a lot of noise insulating sheets, panels, rolls, etc. The main thing is to make the right choice of sound insulators and install them correctly.

Primary soundproofing of doors

General technologies of sound insulationthe material is similar to almost all VAZ vehicles. Differences only in the features of disassembly, assembly of the upholstery and in the number of technological holes. But in any case, first you need to disassemble the upholstery of the doors. When there is only "bare" iron left, it is necessary to carry out treatment with a strong solvent to degrease the surface (acetone, white spirit, 650th, 648th, etc., solvent is suitable). If there is treatment with an anticorrosive compound, then it should not be touched. The primary noise insulation is the installation of a vibration-insulating material (for example, STP). To do this, you need to cut out the sheets that are suitable for the size, heat the lower, bitumen side with a hair dryer and, applying to the metal, roll it out. Making sure that the sheet is well entrenched, take the next piece and fasten it the same way, overlap. The second soundproof layer is a sound-absorbing material. You can use, for example Shumoff, Accent, SPLIT. The latter type of material also has thermal insulation properties. Usually these materials have a self-adhesive basis on one side, so there will be less problems with fastening. It is also necessary to cut the roll or sheets into the largest possible pieces.Technological holes and the last layers of soundproofing

Sealing technological holes increasesnoise insulation effect. However, during repair (replacement), for example, window lifters, door handles will have to cut openings. In addition, if your model provides for the ventilation of the cabin through the doors, sealing the holes will lead to a cessation of the air circulation. If you still decide to close the technological holes, you can stick another layer of soundproofing - although, most likely, it will be too much ; it is more advisable to pay more attention to the door upholstery. To do this, the layer of the vibration isolator will weight the upholstery, - it will vibrate less and make any creaks. Next, glue the layer of bitoplasty, which well "repeats" any shape. At the last stage, you can apply a model, - a material that eliminates creaks between rubbing details (wiring, door handles, etc.). In order not to doubt the quality of the work, in conclusion, install additional door seals.Tip 5: How to install noise insulation

Often to get pleasure at the wheel is notthere is very little - silence. Foreign scratches in the cabin, street sounds can distract you while driving. But all these shortcomings are easily eliminated when installing noise insulation cabin. This work you have to spend the whole day, but then you can safely enjoy music or conversation, even at the highest speed.

You will need

- - set of tools;

- - sound insulation kit;

- - Removable key for pistons;

- - knife;

- - hair dryer building;

- - active cleaner from dirt.

Instructions

1

Disassemble the car interior. Remove the door casing, the ceiling lining, the floor covering, before dismantling the seats. Before dismounting the seats, remove the terminal from the battery. The matter is that in some marks of cars in seats airbags are built in. When removing the seats, the system (electronic control unit) can count this as a signal for triggering and an error will light up on the on-board computer display.

2

Treat the surfaces with a special spray forremoval of contaminants. If it is not, you can wash the interior with water and detergent. All surfaces must be clean and degreased before applying soundproofing sheets for better adhesion. After cleansing, dry the interior well with a hair dryer. The car salon should be warm. Soundproofing do only in a dry and heated room.

3

Distribute sheets of vibration and noise insulation tosalon and cut out curves. Some sections of the salon can be laid with scraps - thresholds, for example. In order to buy the required number of noise insulation sheets, calculate in advance how many square meters of cabin you want to trim. The fact is that noise insulation sheets are sold with a kit with vibration isolation, but their number in the package may be different and depends on the specific manufacturer.

4

Paving noise insulation doors, from the inside underIron put a sheet of vibration isolation, and on the metal part - noise insulation sheet. Laying sheets on the salon, first glue the sheet of vibration isolation, on top of it a sheet of noise insulation. All sheets are glued with adhesive tape.

5

Soundproofing of the torpedo withcloth tape. The elements that you have pasted with sheets, strengthen around the edges with a cloth tape. In this way, you reduce the friction between the plastic elements of the torpedo and reduce the level of various squeaks.