Tip 1: How to change the bearing of the hub

Tip 1: How to change the bearing of the hub

Replacing wheel bearing for rear wheelcars with front-wheel drive of the VAZ line-up is a laborious and complex process. Without special pullers the master in this case can not do. Although some "craftsmen" manage to do this kind of work with a sledgehammer and improvised drills.

You will need

- A set of metalwork tools,

- universal puller for wheel bearings,

- torque wrench,

- locksmith's grip,

- supports for wheels,

- jack.

Instructions

1

To start, you need to install the car onflat surface. Then remove the protective cap from the hub with a screwdriver or special blade from the hub, which prevents the penetration of sand and dust to the bearing of the assembly. With the help of a small beard, unbend the edge of the bearing nut of the hub from the groove of the trunnion. And then unscrew it a little. Place the stops under the front wheels of the vehicle, release the parking brake and engage the reverse gear. After that, for two or three turns, unscrew all four bolts securing the wheel to the hub. Now, with the help of a jack, hang the back of the machine, setting the beam on a secure support, and remove the wheel.

2

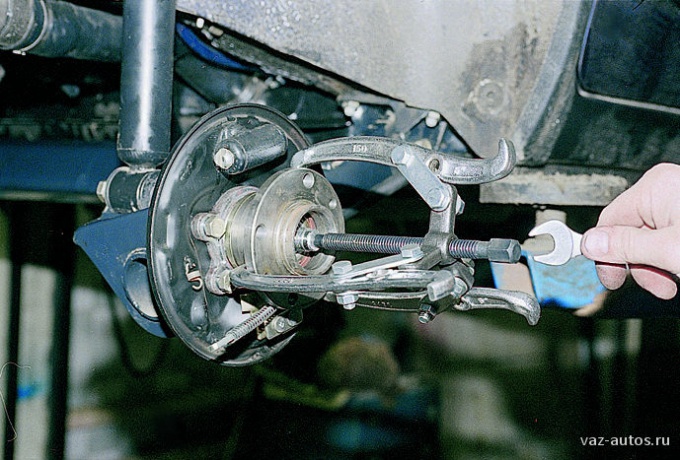

Next, you need to dismantle the brake pads. Unscrew the hub bearing fixing nut completely and remove the steel washer underneath. Using a puller, remove the wheel hub, then tighten it in the metal vise and remove the locking ring that locks the bearing from the inside. Then remove the old bearing from the hub with a puller.

3

The disassembled hub must be washed in keroseneor in diesel fuel, strictly observing the fire safety measures. The assembly is carried out in reverse order dismantling: - the new bearing is pressed in, - the circlip is installed, - the hub is put on the pin, - the washer is inserted and the nut is screwed in, - the brake pads are installed, - the wheel is mounted.

4

By means of a jack the car falls onhard surface, then tighten the new hub bearing nut with a force of 250 N / m, followed by its crocheting in the groove of the trunnion, as well as the bolts securing the wheel disc to the hub. At the final stage, a protective cap is installed.

Tip 2: How to change the bearing on the VAZ 2110

When strong knocking occurs under the hood while drivingon off-road and bumpy is the time to think about replacing the bearing of the rack on your favorite "top ten". Since you will do the repair yourself, then you just need a way to replace the support bearing, which does not require the mandatory adjustment of the wheel alignment angles (convergence).

Step-by-step repair

1. The first thing to do is to detach the tip of the steering rod from the pivot of the rack. To do this, remove the front wheel from the side of the bearing to be replaced with a standard wheel key (or a key with a head for "17") and a jack. Securely fix the car on the base of the factory manufacturing (in no case use a jack for this purpose) .2. Turn the steering wheel to the side opposite the tip of the tie rod. With pliers, unbend and pull out the cotter pin securing the nut of the tip connection to the pivot. Then, with the spanner key on the "19", unscrew not completely the nut of the ball joint of the outer tip of the steering rod. Insert the mounting blade between the pivoting fist and the outer tip, press the tip away from the fist and, striking with the hammer on the end of the pivot, pull the ball joint pin out of the fist. Unscrew the ball pin securing nut and pull the pin out of the hole. With a ring wrench or a head on "13", loosen the tightening bolt of the terminal connection of the outer tip and the slotted screwdriver, unscrew the groove of the terminal connection of the tip. Hold the key on the "22" for the hexagon adjustment rod, unscrew the outer tip, rotating it clockwise, and remove it. Unclip the ball bearing from the pivot knob by unscrewing the two bolts securing the ball bearing to the pivot knuckle with the spanner key on the "17". Then use the mounting blade to pull the suspension arm together with the ball bearing from the pivot. Loosen the head of the front hub bearing on the side of the demountable support bearing by a "30" head. Place rags under the cover of the CV joint to avoid damaging the cover on the front suspension elements. Take the swivel fist with the stand to the side and take out the shank of the SHRUS body from the hub. Position the drive on a stretch. With the wrench on the "17", unscrew the two bolts of fastening the shoe to the steering knuckle and remove the shoe guide assembly with the bracket and shoe from the brake disc. Tie it with a cord to the holes in the wheel arch to avoid excessive tension on the brake hose. With the spanner key or high head for "7" unscrew the two guide pins and remove the brake disc. In case of difficulty, beat the disc with a hammer. Then, with the key for "10", unscrew the three bolts securing the brake disc to the steering knuckle and remove the brake disc shield. With the key on the "22", loosen the stem nut nut by holding the stem from turning the hexagon on "6". With the head or key on the "13", unscrew the three nuts securing the pillar support to the body and remove the stand together with the swivel knuckle assembly. Install the two couplers on the spring diametrically opposite each other so that they engage the three coils of the spring. Evenly rotating the screws of couplers, compress the spring. After the spring no longer presses on the support cup, unscrew the stem nut. Remove the travel stop limiter of the support bearing, and then the support bearing itself. Install the rack with the new support bearing, performing all the operations in the reverse order.Helpful Tips

Before removal of an external tip of steering draftmark its position with respect to the adjusting rod or calculate the number of revolutions when the tip is unscrewed. This is necessary so that when installing a new tip, the length of the steering rod remains the same, which will approximately keep the angle of the wheel convergence. Do not unscrew the stem nut fully until you install the couplers on the springs and make sure that they reliably fix the spring. Otherwise, the spring can "shoot" at you, and you will get a serious injury.Tip 3: How to change bearings

If, when driving on your car, you hearan extraneous rumble in the area of the front wheel, this means that the front wheel bearing has failed and it is time to replace it. You will not make much effort, to make a replacement yourself, if only the tools were at hand.

You will need

- - jack

- - the cross-shaped key (balonnik)

- - two wheel chippers

- - end heads on 12, 17, 19, 30.

- - spanners for 10, 17, 19

- - round pliers

- - Vise

- - hammer and wooden chock

Instructions

1

Install the supports under the rear wheel of the car. Raise the front wheel, which made a hum. After inserting the jack, lift the wheel and rotate it with your hands. Make sure that this bearing is the source of the rumble and must be replaced.

2

Lower the wheel until it touches the ground andtear off first the central nut (for 30 hubs) with a face head. Next, tear off the wheel bolts with a cruciform key (balloon). Again lift the car with a jack, and completely unscrew the wheel bolts, remove it.

3

Turn off bolts of fastening of a brake support anda spherical support to a rotary fist, a key on 17 and 19. Mark on the top bolt of fastening of a shock-absorber rack to a rotary fist. Unscrew both bolts using keys 17 and 19. Twist the wheel studs with the socket head to 12. Gently knock off the brake disc with a hammer and a wooden chuck. Remove the three bolts by 10 and remove the tin dust cover. Remove the hub by unscrewing the nut by 30.

4

Remove the two retaining ringsbearing from the hub. With a mandrel and a hammer, remove the old bearing from the hub. Check the bearing seat, it should be without visible damage. Replace the outer circlip. Vise press the new bearing into the hub. Install the second snap ring.

5

Reassemble in reverse order.

Tip 4: How to change the front pads

The front pads of the car experience a largeload when braking than the rear. For the normal operation of the brake system, it is necessary to replace them in time. Periodicity of inspection of the front blocks should be no more than 15 000 km. Pads should be replaced if the friction pads are worn down to 1.5 mm.

You will need

- - balloon wrench;

- - jack;

- - emphasis on the car;

- - pliers;

- - Phillips screwdriver;

- - mounting blade;

- - a hammer;

- - metal brush.

Instructions

1

Install under the rear wheels of the carwheel rolls, pull out the parking brake lever. Loosen the front wheel bolts. Lift the front part of the car with a jack, insert the stops and remove the front wheels.

2

Check the brake fluid level in the reservoir if you close the maximum with a syringe or rubber pear. Do not twist the lid, to avoid squeezing out the liquid through the cuffs.

3

With a metal brush, clean the dirt of the brakes. Lubricate the guide pins with WD-40 liquid lubricant or any other penetrating lubricant.

4

With pliers, remove the cotter pins from the guidespins. With a hammer, carefully remove the pins from the brake cylinders using a screwdriver or a metal piercer of suitable diameter. Remove both wire locking springs from the brake pads.

5

Carefully insert the mounting blade betweenbrake shoe and brake disc. Press the piston into the brake cylinder. You can also use sliding pliers. Repeat the operation with the second shoe. It is necessary to monitor the level of fluid in the brake tank, the excess fluid must be pumped out.

6

Remove the brake pads. Clean the seats of the shoes from dirt. Do not use gasoline or other solvents to clean the brakes. Replace the new brake pads.

7

Lubricate the guide pins before installing them with grease. When installing the pins, insert the pressure springs. Secure the guide pins with special spring keys.

8

Install the front wheels. The final tightening of the wheel bolts is done when the car is completely on the ground. To install the brakes in the working position, press the brake pedal a few times until it stops.

9

Check the brake fluid level in the reservoir andtop up if necessary. Take care the first 10-15 km of the road, until the pads are not pinned to the brake discs, tk. The efficiency of the brakes will be reduced.

Tip 5: How to install the bearing

All machines have parts that arethe work process is spinning and spinning. This leads to friction, heat and wear. To avoid these problems, bearings are installed on the shaft support sections. Due to this, wear of parts from long friction and heating is reduced.

You will need

- - a hammer;

- - a piece of pipe.

Instructions

1

Installation of the bearing is carried out in severalstages. On the first, check and prepare the bearing and the assembly where it will be installed. Clean the surface of the rust, old grease and dirt. Also check how much it is worn, otherwise the bearing on such surface will rotate, as a result of which the work of the entire unit will be disrupted. If the damage is insignificant, remove them by grinding. On the surface, which is prepared for the installation of the bearing, apply a small layer of lubricant.

2

New bearing to be installedshould be in a sealed plastic bag containing a preservative grease that promotes its long-term storage. After opening the package, remove the bearing and wash it in gasoline. If there is a protective washer on it, it is not necessary to flush the bearing.

3

To install the bearing, you need a piecepipes of soft metal, suitable for the size of the inner or outer ring of the bearing. If you install it on the shaft, the frame should fit under the inner ring, if mounted in the body - under the outer ring of the bearing. Install the bearing not with strong blows of the hammer on the rim, which, in turn, must be attached to the corresponding bearing ring. Note that the load applied must be uniform. In addition, you can not attach it directly to the bearing rings or to a number of rolling bodies.

4

During the installation of the bearing, make sure that it is installed on the shaft or in the hole without distortion, as this can cause the surface of the bearing or the assembly to bulge.

5

Having established the bearing, grease a surface of bodies of a rolling with greasing. Bearings having protective washers or o-rings already contain factory grease, so they do not need it.

Tip 6: How to replace the front hub bearing on the VAZ 2110

Front Wheel Bearingalways in motion are subjected to enormous loads, which are many times amplified when driving on poor-quality road cloth. For this reason, the front hub bearings wear out more often than other parts of the machine. Repair of the bearing of the front hub VAZ 2110 and similar models consists of constant inspection, regular lubrication and complete replacement of the bearing in case of failure.

Methods of bearing replacement

Replacement of the front hub bearing VAZ 2110 canis produced by one of three methods. The first is to replace the bearing with a special puller without removing the rotary knuckle from the machine. The second is the replacement of the bearing with the dismantling of the swivel fist using a puller and vice. The third method is to completely remove the rack from the car and replace the bearing in a vice. All described methods have their pros and cons. When replacing the hub bearing, the first method is not to untwist the camber adjustment bolt, which is a great advantage of this method. The main disadvantage is uncomfortable work, in which the replacement of the bearing without a special lift, trestle or inspection pit becomes quite problematic. When using the second method, bearing replacement becomes an easier task, but a problem arises in violation of camber adjustment. In order to avoid this violation, before twisting the pivot bolts, two marks must be made. One of them should show the location of the adjusting bolt relative to the post, the other - the position of the pivot. After replacing the bearing during the assembly process, it is necessary to match the marks. Achieve initial accuracy is unlikely to work, but the error will be small. This method is ideal for those who, apart from the bearing of the hub, replace other parts of the car's running gear. Of all the methods, the third is the most difficult. To dismantle the rack, you need to press out the steering tip, unscrew the nuts that attach the upper support to the car body, then replace the front hub bearing on the dismantled rack. This method is more complicated than the others, but they are sometimes used when the two previous methods for some reason do not fit.Instructions for replacing the bearing using a puller and vice

To begin, put the car on the "handbrake" andturn on the first gear, then insert safety stops under the rear wheels for safety reasons to prevent rollback. Then loosen the wheel bolts and "hang" the front of the car (both front wheels). Using a spanner with a 30 mm hole, unscrew the hub bearing nut. In the event that light alloy wheels are used in the car, you must first dismantle the wheel itself and invite an assistant who will keep the brake pedal depressed until the second person untwists the hub nut. Using a screwdriver, try to squeeze the caliper, then remove the caliper from the pivot with a key of 17 mm. Tie the caliper so that it does not hang on the brake hose. Then remove the brake disc from the front hub. After that, do not forget to specify tags. Unscrew bolts of fastening of a rotary fist to a rack and with the help of a soft beat them out. Remove the two bolts that secure the lower ball joint to the pivot, then remove the latter. Knock the hub out of the bearing with the correct diameter. Remove the snap ring. Install a special puller in the vice and start pressing the bearing. After this, it is necessary to clean and lubricate the bearing seat. Then proceed to press the hub bearing, put the lock ring. Turn the rotary knuckle with the new bearing to the hub and use a mandrel of the correct diameter to drive it to the stop, the force being applied to the inner diameter of the bearing ring. The next assembly must be done in the reverse order. After the nut of the bearing of the hub is tightened, it is necessary to crush its edge.Tip 7: How to change the bearing of the generator to VAZ 2110

From the engine compartment of your tenthere is a shrill shriek and howl as soon as you get the car, and when the generator belt is removed, the noise disappears? You can be sure: in your car the generator's bearing has failed.