Tip 1: How to remove the abs sensor

Tip 1: How to remove the abs sensor

Sensors anti-lock braking system (ABS)are located on the turning fists of the front wheels or the hub assemblies of the front and rear wheels. You can find out the installation of ABS sensors with the help of the factory instruction. Lift the front part of the car with a jack. Place the machine on the supports. Remove the corresponding front wheel to open access to the parts.

Instructions

1

Raise the front of the car with the jack. Place the machine on the supports. Remove the corresponding front wheel to open access to the parts.

2

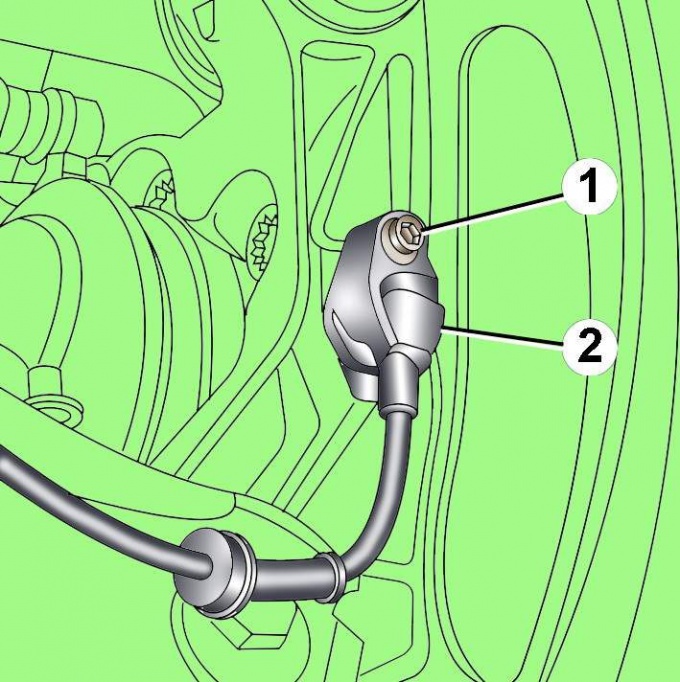

If the sensors are mounted on rotary fists,Unscrew the bolts securing the sensor to the rotary knuckle. Carefully remove the sensor from the rotary knuckle at the point of attachment. Through the free opening, release the sensor cable and detach the plug connector. Clean the sensor mounting hole and the sensor from dirt. Similarly, ABS sensors on the rear wheels are removed.

3

To remove the ABS sensor rotor, remove the caliperthe corresponding brake mechanism and tie it to the suspension mechanisms without disconnecting the hydraulic drive. After removing the ABS sensor, mark the brake disc relative to the hub and remove this disc. Loosen the hub nut. Remove the anti-roll bar. Release the ball joint from the hub assembly by loosening the nut of its mounting.

4

Knock out the spring pin of the innerSHRUS and remove a power shaft in gathering. Disconnect steering draft from a nave and release spherical hinges. Noticing the location of the head of the bolt, unscrew the hub mounting bolts to the suspension bracket. Remove the hub assembly. Remove the hub from the hub assembly by pressing it out. Remove the rotor of the ABS sensor by unscrewing its mounting bolts to the hub flange. Rotors ABS sensors on the rear wheels are removed similarly.

5

Install the sensor in reverse order. If the rotor has been removed, when assembling the hub, replace the spring pin of the inner CV joint and the hub nut. Check the tightening torques of all connections in accordance with the manufacturer's recommendations. Adjust the air gap between the sensor and its rotor. After assembly, check the serviceability and operation of the ABS.

6

To adjust the air gap between the sensorand its rotor, measure the gap between the ABS sensor and each of the 44 teeth of its rotor. Compare the measurement results with the requirements of the specifications. If there is insufficient clearance, adjust it with a special tool. If the gap is too large, replace the rotor or ABS sensor.

Tip 2: How to remove the ball joint

If from the direction of the front wheel a knock is heard during the ride, you know: the ball bearings are asked for replacement, at least the top ones. The lower ones do not knock, but they should also be replaced. How to remove the ball?

Instructions

1

It is required to remove the wheel. It is necessary to unscrew the wheels for convenience. When working with the wheel on the right - until it stops to the right, with the left wheel - to the left.

2

For insurance, put a "goat" under the car. To unload the chassis under the lower arm, you can put a wooden beam. Using a jack, lower the car on it.

3

Using a car key, unscrew the nuts. They hold the fingers of the ball joints. It is required to make sure that the height of the jack is optimal for the passage of the key between the structure of the spring.

4

When the nut is unscrewed, beat the finger. Using a hammer, hit not on the finger, but on the area a little lower. After a few strokes, the finger of the ball joint will come out.

5

Unscrew the lower ball pedestalI.e. a nut that holds a finger. Knock out the bottom ball with a hammer just in the area just below the finger. After its exit, twist the nut.

6

Diagnose the ball bearings without removing it from the lever. You can proceed to unscrew the ball levers. Use two keys - regular and ratchet. The ball joint is removed.

Tip 3: How to remove the front hub

The reason for removing the front hub of the car,as a rule, becomes wear of its bearings, which is evidenced by the appearance of extraneous noise emanating from the wheel of the car while driving. To be sure of the correctness of your suspicions about the impending failure of bearings, it is necessary to determine in which hub (right or left) a malfunction occurred.

You will need

- - jack,

- - a key for wheels,

- - Hub key.

Instructions

1

At the preliminary stage in preparation for theupcoming repair, the car is installed on a level platform. The shift lever is moved to neutral, the parking brake lever rises as far as possible, and the chocks are installed under the rear wheels.

2

After that, both front wheels, which are scrolled by hand in order to detect the noise of the bearings, are raised in a row by a jack.

3

Determining in which hub arosemalfunction, the car is lowered on a jack, and four bolts of its fastening are released on the wheel, and the nut for fastening the bearings of the specified assembly is turned off for two or three turns.

4

Then the machine rises again on the jack, and the corresponding side is mounted on a rigid support.

5

Further, the wheel is dismounted from the machine, and after it is removed, the bolts of the front brake caliper mounting are unscrewed.

6

After releasing the specified brake mechanism from the attachment, it is removed to the side, so that it does not interfere with further repair, and then the nut of the bearing fastening on the pivot pin (or the joints) is loosened.

7

At the final stage of dismantling the front hub, it is removed (if lucky) with your hands or with a universal puller.

8

After replacing worn bearings, all subsequent assembly steps are carried out in the reverse order.

Tip 4: How to remove the ABS sensor

Anti-lock braking system (ABS) is a system,It prevents the wheels from blocking abruptly when braking. It helps with sudden braking not to lose control of the vehicle and to abolish slip. To date, ABS is a sophisticated electronic system, which includes an anti-slip system and an electronic stability control system. Sensors ABS are on the wheels of the car, and when checking the health of the system they must be removed.

Instructions

1

In order to remove the ABS sensor from the front wheels,First of all, disconnect the wire from the negative terminal of the battery, which will ensure your safety. If the wheels are fitted with caps, then remove them, for "casting" no intermediate steps are required. After this, be sure to place the car on the handbrake and loosen the bolts.

2

Lift the front of the car withjacks and fix on stands, or use a lift. Carefully remove the front wheels. Find the electrical connector of the sensor, which is usually located under the wheel arch in the fastening bracket. Take it out, and then disconnect the connector itself with a screwdriver.

3

Unscrew the bolt with which the ABS sensoris attached to the bracket, and remove the sensor. Carry out its inspection, inspection or replacement. Check the condition of the O-ring and, if necessary, replace it. Installation is in the reverse order.

4

Removing the sensor from the rear wheels is madeSimilarly, the difference is only in the place where the sensor is attached - it is most likely connected to the longitudinal arm of the rear suspension or to the bracket. After installation check up serviceability on a control lamp on the panel of devices - it should die out right after the engine has started.

Tip 5: How to put abs

ABS - anti-lock braking system, whichallows you to drive the car with a sharp braking, even on a slippery road. It consists of three components: sensors on wheels that fix the speed, an electronic unit that processes the information, and a modulator that changes the pressure in the braking system, which prevents the wheels from going to the ground.

Instructions

1

Install the hydraulic modulator and the unitelectronic control ABS. Place the ABS on the hydromodulator. First place the sealing element, install the system and tighten the bolts with which the control unit will be attached to the hydromodulator. Ensure that the electronic control unit is not deformed during installation. Then connect the wiring.

2

Place the modulator with ABS on the support bracket and install them into the engine compartment. At the top of the modulator there is a special connector that has many contacts - connect it.

3

Connect the brake pipes to the master cylinder and modulator. Take the spanner with the split head. So you prevent the rounding of the nuts.

4

Put on the main brake tank covercylinder, pre-pouring a liquid there. Note that the brake fluid is a very strong chemical compound, which when attacked on the paint surfaces corrodes them. Then attach the brake tube holder. Establish a basic arm and the relay, its assembly block, having thrown on it three fixing nuts. Place the wiring harnesses in the bracket. Fasten the cover of the mounting block by inserting it into the support bracket.

5

Connect both multi-pin connectors to thethe mounting bracket of the relay. Attach the battery pack. Note that the modulator is not recommended to be turned during installation. a large loss of liquid is possible.

6

Bleed the brake system. Spend the flow in goggles. First, press the foot brake when the engine is not running. Then, adding the brake fluid to the required level, pump until the air is completely removed from the system.

7

Integrate the wheel sensors in the form of coils with magnetic cores in the wheel hub.

Tip 6: How to remove the hub from the pivot on the VAZ 2109

Removal of a nave of a wheel is necessary for replacementa failed bearing and requires certain locksmith skills and a special tool. The bearing does not require adjustment during installation and installation work can be carried out independently.

Tools and equipment

For the manufacture of work on the removal of the hubThe following tools and equipment will be needed on the VAZ-2109: - a jack - a balloon wrench - an end head for the hub nut - wrenches for 12, 17 and 19 - a screwdriver - a bearing for pressing out the bearing of the hub.Sequence of work execution

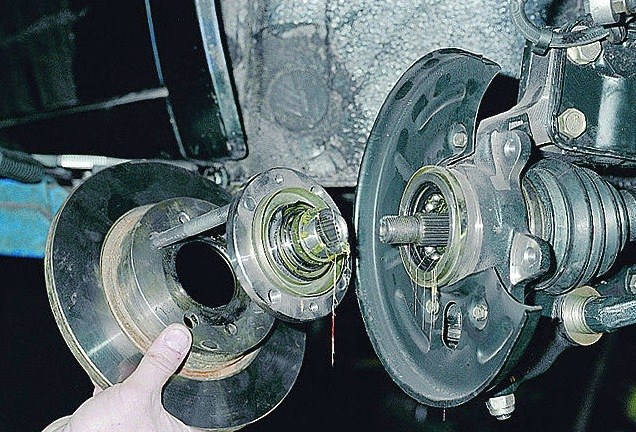

On a car standing on the ground, remove the protectivea cap of a nave nut and uncut a nut. Then loosen the end cap of the hub nut and the bolts securing the wheel. The nut of the hub is tightened with great force, so for loosening it is necessary to use some lever, for example a suitable piece of pipe. Further lift the car a jack and place under it an emphasis. To work without an emphasis is strictly not recommended. Now you can completely unscrew the hub nut and remove the wheel.When removing the hub, the bearing collapses, so press out the hub only to replace the bearing.Then remove the brake disc, for this in the beginningUnscrew the two bolts securing the brake cylinder to the pivot. Without disconnecting the brake hose, remove the entire brake assembly and hang it with a wire on the rack spring. Make sure that the brake hose is not stretched or twisted. Clean the brake disc from dust and dirt with a metal brush. Apply WD-40 liquid grease to the hub and brake disc connection. Leave on for 30-40 minutes until the rust dissolves. Turn out the guide pins and remove the brake disc, if necessary, tapping the kyanik, trying to hit closer to the center of the disc. Mark the position of the eccentric bolt with respect to the rack body and loosen the nuts on the bolts securing the swivel fist to the post. Turn out bolts of fastening of a spherical support to a rotary fist. Unscrew the nuts completely on the bolts securing the knuckle to the bracket on the front pillar, remove the bolts and pull the swivel fist out of the rack.

If there is no special mandrel, you can press out the hub using old rings from the bearing.Using the mandrel, press out the hub from theinner bearing ring. If part of the ring is left on the hub, remove it with a special puller, a special groove is provided for this on the hub. Remove the locking rings on both sides of the rotary cam and press the bearing out with a special mandrel. On this work to remove the hub and vypressovke bearing on the VAZ-2109 are finished. Before installing the new bearing on the hub, first replace the outer retaining ring.