Tip 1: How to change the ball to Renault Logan

Tip 1: How to change the ball to Renault Logan

The malfunction of the ball joint is easy to detect. Extraneous sounds from the front wheels, backlash at the bottom of the hub. Even if the anthers are damaged, the ball supports need to be changed.

Instructions

1

Prepare the car for repair. To do this, install wheel chocks under the rear wheels. To be sure, turn on the handbrake, it will not be superfluous. Carry out a replacement ball should be in the car with the front wheels removed. Lifting both sides of the car, you will weaken the stabilizer of the lateral stability, it will not interfere with the repair. First, unscrew the wheel bolts, then lift one side, place a safety support underneath it, then lift the second side, you also need to install a support under it. Remove the wheels after installation on the safety levers.

2

Process threaded connections penetratinggrease. Elements of the front suspension are constantly in the water and dirt, so rust is a common occurrence. To make things a bit easier, you need to disconnect the steering rods from both sides. And only after that you can start dismantling the old ball joints. For this, special pullers are not needed, all work is done by improvised means. The first thing to do is to unscrew the bolt that fastens the finger of the ball bearing to the wheel hub. To do this, on the nut, put on the carabiner wrench at 17, and unscrew the bolt head with a socket wrench at 17.

3

Knock out the bolt from the hub with a breakdown. Now it's time to remove the finger of the ball bearing, for this you need to install a sturdy screwdriver in the slot on the hub. Due to this, the finger freely leaves the hub. Now pull the hub to the side and start dismantling the ball joint. First thing at the top, remove the snap ring, which does not allow the ball to fall down. But even after removing the ring, it will be quite problematic to dismantle the old ball, because it is tightly pressed into the lever.

4

Take a piece of pipe, whose inner diameterslightly larger than the diameter of the ball joint. This piece of pipe must be put under the lever, the lower part to rest in the ground. The ball must enter this tube. Now, using a hammer, you need to carefully push out the ball from the seat. After that, you can install a new one. It must be pressed using the extension. Do not hit on a new ball, as this may damage it. Along with the ball, always change the bolt that fastens the finger to the hub. Assemble in the reverse order, do not forget to install the steering rod into place. The left and right sides are treated equally, there are no significant differences.

Tip 2: How to change the ball joint

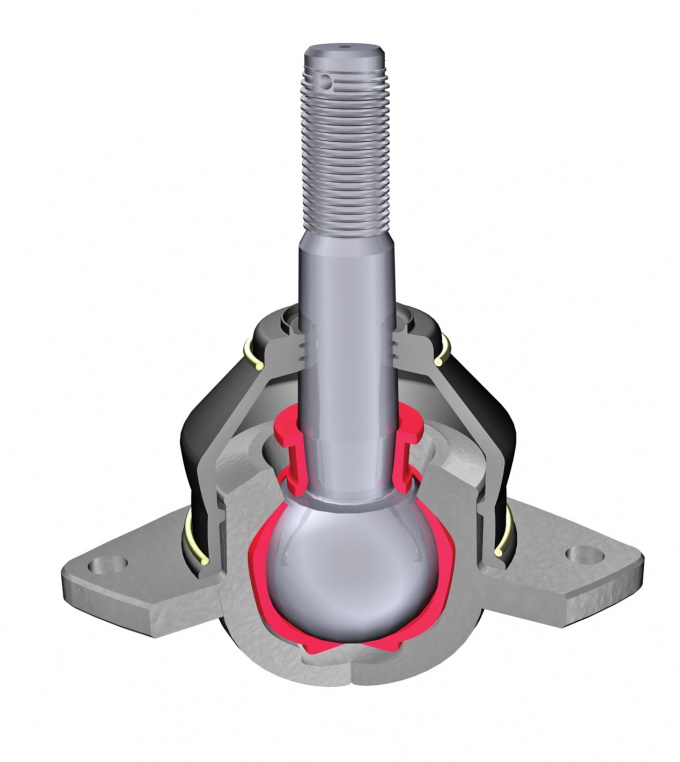

Ball bearings are important elementscar suspension. They provide a swivel connection of the front suspension levers with a rotary knuckle and transmit various kinds of loads from the wheels to the body of the car while driving with simultaneous turning and a vertical stroke of the wheels. Most balloon "fly" on the bumps. Therefore, we must carefully monitor their condition and, if necessary, change.

You will need

- A jack, a key "for 22", a hammer (or a special puller).

Instructions

1

First you need to remove the load from the suspensioncar. To do this, you need to subdivide the car and remove the wheel from the hub. Then place under the lower lever any sturdy stand and lower the car so that the lever rests securely on the stand.

2

Then use the key "for 22" to unscrew the nut of the ball bearing.

3

Then sharp blows of a hammer on a ledge of a rotary fist (in a place of a location of a spherical support), it is necessary to achieve exit of a spherical ball from its seat.

4

After that, using a "13" key, you need to unscrew the three nuts on the bolts securing the ball joint to the lever. Then you can remove the ball pedestal. But the main thing is not to forget to remove the plate, and when assembling - to put it in place.

5

Installation of a new ball joint is carried out in the reverse order.

Tip 3: How to remove the ball joint

If from the direction of the front wheel a knock is heard during the ride, you know: the ball bearings are asked for replacement, at least the top ones. The lower ones do not knock, but they should also be replaced. How to remove the ball?

Instructions

1

It is required to remove the wheel. It is necessary to unscrew the wheels for convenience. When working with the wheel on the right - until it stops to the right, with the left wheel - to the left.

2

For insurance, put a "goat" under the car. To unload the chassis under the lower arm, you can put a wooden beam. Using a jack, lower the car on it.

3

Using a car key, unscrew the nuts. They hold the fingers of the ball joints. It is required to make sure that the height of the jack is optimal for the passage of the key between the structure of the spring.

4

When the nut is unscrewed, beat the finger. Using a hammer, hit not on the finger, but on the area a little lower. After a few strokes, the finger of the ball joint will come out.

5

Unscrew the lower ball pedestalI.e. a nut that holds a finger. Knock out the bottom ball with a hammer just in the area just below the finger. After its exit, twist the nut.

6

Diagnose the ball bearings without removing it from the lever. You can proceed to unscrew the ball levers. Use two keys - regular and ratchet. The ball joint is removed.

Tip 4: How to Change Stabilizer Stands

The most important elements of the suspension of a modern car are racks stabilizer. Their failure will not only affect the runningcharacteristics, but it can also cause a serious accident. The appearance of knocks in the front of the suspension when the car passes through irregularities may indicate the need to replace the racks stabilizer.

Instructions

1

First of all, you need to carefully consider the choicenew racks. These suspension elements can not be bought "by sight", taking into account only the external similarity in length and angle of inclination. Despite the fact that most racks stabilizer visually it seems that they should not be considered interchangeable. Buy only such racks, which are designed for your model.

2

To replace the racks, you need to post a carAt the lift or jack at least one axis. This is done in order to bring the suspension into balance. With the hanging of only one wheel, the stabilizer will pull the suspension down and even with the successful removal of the old racks you can not install the new one correctly anyway.

3

To unscrew the rack, grab the face with the keya ball finger and having fixed the tool, turn away a rack. After removing the old part, replace it with a new one and press the nuts. Do not tighten the nuts to the stop - they can be tightened only after the machine has been lowered and the rack takes up the working position.

4

Be especially attentive to anthers that are hinged racks and protecting it from moisture and dirt, which leads to a rapid wear of the part. Damage to anther is very easy, so make sure that the key does not fall off when unscrewing and twisting the nuts.

5

At the factory, usually racks Put on transport caps, which serve to protect the anthers. They should be removed before installation, otherwise the rack stabilizer in a very short time again will fail.

Tip 5: What is the Ball Bearing for?

Ball joint is designed for wheel couplinghubs with a rotary control lever, allowing them to freely rotate each other. To protect against moisture and dust, the ball bearing has a rubber cover.