How to replace bearings in a washing machine

How to replace bearings in a washing machine

Modern household appliances are designed forlong-term operation and has a great resource. If the washing machine is broken, do not rush to throw it away and run to the store for a new one. The mechanical part is most susceptible to various damages. Its independent repair is not very difficult.

You will need

- - screwdriver "on the cross";

- - a set of hexagons;

- - New bearing and cuff.

Instructions

1

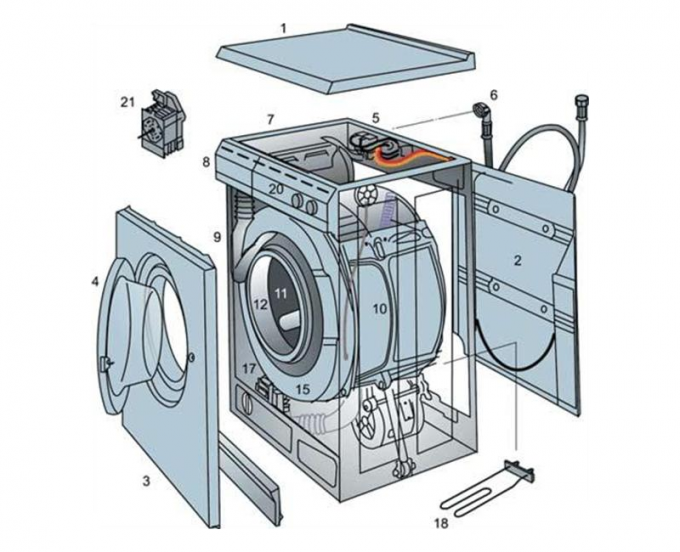

Unplug the machine from the mains, the water mains andsewage system. To remove the drum, it takes a lot of space, so it's better to pull the car out into the middle of the room. Inspect the back of the washing machine. Locate the screws securing the top cover, unscrew them. Remove the cover. Below it you will find a load that is designed to reduce vibrations. The load is attached to the drum through spring supports. Unscrew the screws securing the supports, remove the load by lifting it up. Under the load you will see a tank.

2

Using a screwdriver, remove the self-tapping screws thatThe back cover of the washing machine is attached. Remove it. Disconnect the wires of the motor, heating element, water level sensor. Disconnect the drain hose. Open the hatch to load the laundry. Carefully, without exerting great effort, remove the rubber seal between the body and the drum. Now the tank rests on the body of the washing machine through the lower spring supports. Remove it from the top cover.

3

Next, you need to disassemble the tank of the washing machine. In older models, it is easy to do this - the tank halves are bolted together. Unscrewing them, you can easily remove the lid and access the drum. But if the technique is relatively new, the tank may not be collapsible. The cost of a new tank is comparable to the cost of a washing machine. Therefore, armed with a knife for metal, boldly saw the tank on the seamed joint. While the tank is still assembled, drill through at regular intervals 8-10 holes at the edges of the joint. They are useful when assembling. Therefore, it is better to drill them in advance. Disconnect the tank halves. Access to the drum is open.

4

Remove the drive belt of the electric motor, the pulley withaxis of the drum. Remove the drum from the tank. In the rear half of the body on the inside is a cuff-closed bearing. Remove the cuff, remove the bearing. Install a new one in its place, close the cuff. Reassemble the washing machine in the reverse order. If the drum had to be sawed, insert the bolts into the holes drilled beforehand, by means of which tighten the drum halves to each other, pre-sealing the joint with a sealant.